Why pallet wrapping machine repair is important for every company

Wiki Article

All Regarding the Benefits of Buying a Quality Pallet wrapping Machine

Purchasing a high quality pallet wrapping maker can transform product packaging procedures. These devices give enhanced Load security, making sure that products continue to be secure during transport. They also decrease material waste by using stretch film successfully. Nevertheless, the advantages extend beyond these points. Discovering the complete series of advantages exposes a much deeper effect on productivity and safety and security within the work environment. Comprehending these advantages can cause more educated service decisions. What other factors should be thought about?Improved Load Security

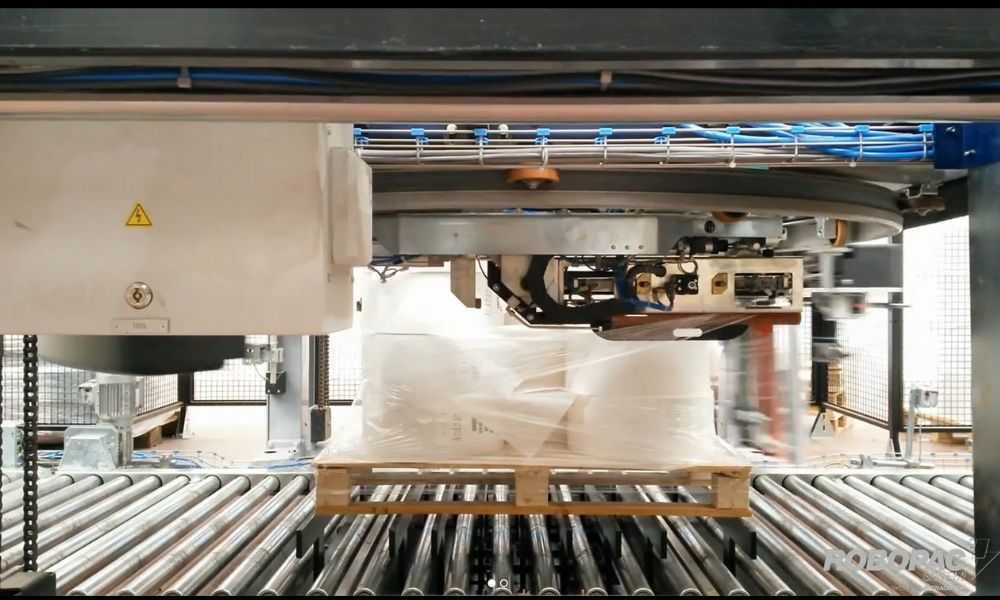

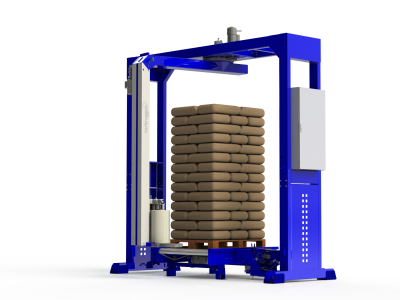

Boosted Load security is a crucial advantage of buying a pallet wrapping maker. This equipment plays a vital duty in safeguarding lots throughout storage and transportation, minimizing the threat of toppling or shifting. By tightly wrapping pallets with stretch film, the equipment guarantees that specific items stay in location, securing them from damage. Improved security additionally enables much safer handling, decreasing the chance of crashes and injuries in the office. With enhanced Load stability, firms can optimize space application in shipping containers and storage facilities, leading to extra reliable procedures. Eventually, the increased dependability of palletized tons cultivates self-confidence amongst vendors, companies, and consumers, enhancing total supply chain effectiveness and reliability.Reduced Material Waste

Boosted Efficiency and Rate

Buying a pallet wrapping equipment substantially increases performance and speed in product packaging operations. These makers automate the wrapping process, enabling quicker prep work of products for delivery. By decreasing the time spent on hand-operated wrapping, organizations can improve throughput and lessen bottlenecks in the operations. Additionally, pallet wrapping makers offer regular results, making sure that every Load is covered uniformly, which gets rid of the requirement for rework. This reliability not only accelerates procedures yet likewise adds to far better supply administration, as items are prepared for distribution extra swiftly. Overall, the combination of a pallet wrapping machine leads to a considerable boost in performance, permitting firms to meet client demands better and keep an one-upmanship in the marketplace.Boosted Worker Safety And Security

Decreased Manual Handling Threats

Executing a pallet wrapping maker significantly decreases hands-on dealing with risks, boosting general worker safety and security in commercial atmospheres. Traditionally, employees manually wrapped pallets, revealing them to various physical stress and injury dangers, consisting of training and turning. By automating this process, the maker reduces the need for employees to take part in recurring, laborious tasks that can cause bone and joint disorders. Additionally, the safe and secure and regular wrapping provided by the machine minimizes the possibility of product moving or falling throughout transportation, lowering the danger of mishaps. This not only secures the employees yet likewise assures the honesty of the items being handled. Overall, buying a pallet wrapping equipment cultivates a more secure office atmosphere by minimizing hands-on dealing with dangers properly.

Enhanced Ergonomic Style

The boosted ergonomic layout of pallet wrapping equipments substantially adds to boosted worker security and comfort. These machines are crafted to decrease physical stress by enabling operators to maintain a neutral body posture throughout procedure. pallet wrapping machine repair. Attributes such as flexible elevations and straightforward controls allow efficient handling without extreme reaching or flexing. Additionally, numerous designs include safety and security guards and automated shut-off systems to prevent accidents, additionally safeguarding workers. By decreasing the physical needs of wrapping pallets, these machines lower the danger of bone and joint injuries and tiredness, promoting a much healthier work environment. Generally, purchasing an ergonomic pallet wrapping device not only enhances performance but also demonstrates a dedication to employee well-being and safetyCost-efficient Packaging Solution

While numerous services seek effective means to enhance their operations, a pallet wrapping machine attracts attention as an affordable product packaging solution. By automating the wrapping procedure, firms can significantly minimize labor expenses and decrease the time needed for product packaging. This performance converts to greater productivity degrees, allowing organizations to allocate resources to other necessary areas. In addition, a pallet wrapping device aids to reduce product waste, as it uses the ideal quantity of stretch film required to secure items without unwanted. This not only brings about savings on product packaging products but additionally boosts the honesty of the products during transport. In general, purchasing a pallet wrapping machine shows to be a smart economic decision for companies aiming to enhance their product packaging operations.Personalization and Convenience

Customization and flexibility are vital benefits of investing in a pallet wrapping machine, permitting businesses to customize their product packaging processes to details product needs. These machines frequently feature flexible setups to suit numerous dimensions and forms of pallets, making certain perfect wrapping for various lots. Individuals can select the kind of wrapping stress, density, and product to enhance effectiveness and satisfy particular operational needs. Additionally, advanced designs offer programmable features, enabling fast changes between different packaging tasks without substantial downtime. This adaptability not just improves the product packaging procedure but also boosts performance by lessening hand-operated adjustments. Therefore, business can efficiently reply to varying demands while preserving a high criterion of presentation and functionality in their product packaging solutions.Better Item Security Throughout Transportation

Making sure products get here intact at their location is a vital worry for businesses, and spending in a pallet wrapping maker considerably improves item security during transportation. These devices apply a secure layer of stretch film around pallets, developing a stable unit that lessens movement during delivery. This added stability aids avoid damages from moving tons, ecological elements, and influences that can happen throughout the transport process. In addition, high quality pallet wrapping machines can supply moisture resistance, protecting items from damp conditions. By effectively sealing and protecting things, services can reduce the threat of loss and costly returns as a result of damaged goods. Eventually, buying a pallet wrapping machine proves vital for preserving item integrity and making certain customer fulfillment.Regularly Asked Inquiries

For how long Does It Take to Mount a Pallet wrapping Equipment?

The installation time for a pallet wrapping maker commonly varies from a few hours to a pair of days, relying on the machine's complexity and the center's readiness to suit the devices.What Maintenance Is Required for a Pallet wrapping Maker?

Normal maintenance for a pallet wrapping machine includes lubricating moving parts, checking and replacing worn components, cleaning up the equipment, and making certain correct calibration. Scheduled inspections assist avoid breakdowns and expand the tools's lifespan, enhancing functional performance.Can a Pallet wrapping Equipment Manage Various Pallet Sizes?

A pallet wrapping device can commonly take care of different pallet sizes, relying on its style and requirements. pallet wrapping machine repair. Flexible setups and features enable operators to suit various measurements, guaranteeing reliable and safe wrapping for varied tonsWhat Is the Typical Lifespan of a Pallet wrapping Device?

The typical life expectancy of a pallet wrapping machine usually ranges from 5 to 15 years, depending upon the model, use frequency, upkeep methods, and operational atmosphere, influencing general efficiency and long-lasting financial investment value.Are There Any Kind Of Specific Training Requirements for Running These Makers?

The training demands for running pallet wrapping devices generally consist of safety and security procedures, maker operation techniques, and upkeep procedures. Proper training guarantees risk-free use and takes full advantage of effectiveness, lowering the danger of accidents and equipment damages in the work environment.Furthermore, pallet wrapping makers give consistent outcomes, making certain that every Load is covered consistently, which eliminates the requirement for rework. Spending in a pallet wrapping machine significantly improves employee safety by lowering the threats associated with hands-on handling. Routine maintenance for a pallet wrapping equipment includes lubricating moving more info parts, examining and changing used parts, cleansing the equipment, and making certain correct calibration. A pallet wrapping machine can normally deal with different pallet dimensions, depending on its design and requirements. The training needs for running pallet wrapping devices generally consist of security methods, machine operation strategies, and maintenance procedures.

Report this wiki page